Ramping up to IBA 2023, the world’s most important event in the bakery sector, IMA FLX presents the solutions to be showcased in October at the Münich venue – Stand B1.310.

Already a familiar name supplying turnkey processing and packaging solutions to several industries,IMAfocuses on the food sector through one of its best-established clusters known asIMA Flexible Packaging hub, whose expertise in flexible packaging solutions covers the current and future needs of the bakery sector.

Focus on the future of the bakery sector

However, being a well-known player is far from the objective IMA has set itself in order to keep pace with a market that evolves rapidly from one year to the next. In fact,IMA FLXis investing substantial resources into cutting-edge technologies and new machines that will attract the forward-looking manufacturers, those who intend being the key players in this industry over the next decade and more.

Today, IMA FLX is made up of different brands whose integrated experience and variety of solutions have given rise to the most comprehensive flexible packaging hub serving the bakery sector. Driven by IMA Group’s company culture that pioneers sustainability in every aspect of business or technology, IMA FLX represents a one-stop supplier that is best-placed to support bakery manufacturers looking to deal with tomorrow’s trends as leaders in their own market. IMA FLX is developing numerous technical solutions to handle a wide range of eco-friendly materials that pose different processing challenges, but are likely to become the preferred packaging films in the near future.

At a glance, IMA FLX is a kaleidoscope of specialist companies

IMA FLX’s team of specialists take great pride in their many years of hands-on experience in the bakery industry. This field-tested know-how is expertly applied to the wide range of reliable, flexible and innovative packaging machinery and complete automatic lines designed and manufactured with bakery industry requirements in mind. IMA manages your product from the oven/freezer exit to handling, feeding, dosing, primary, secondary and end-of-line packaging.

From fresh cakes, bread and pizza to biscuits, frozen dough and prebaked products, each application has its own unique packaging requirements and theIMA FLXhub companies–IMA Ilapak, IMA Record, IMA Delta Systems and IMA Eurosicma– offer the best solution for each of these applications, customised when needed. With such an array of competences, the bakery sector can rely on this cluster of expert brands to deliver a turnkey solution which will enhance performance and bring the customer a competitive edge.

Completing the process with the latest end-of-line solutions

No line would be turnkey in the true sense of the word without the necessary technologies to complete the packaging process. TheIMA End-of-Linehubrepresents a strategic asset for all the divisions within the IMA Group and a unique solution provider of secondary packaging technologies for a broad spectrum of industries, including those in the bakery sector.

Each company within the hub brings a specific expertise.IMA BFB is a leading brand in end-of-line technologies ranging from robotic handling to overwrapping, case packing and palletizing. IMA Ciemme is an expert manufacturer of carton packaging machinery, closing, forming and automatic loading technologies. IMA Mespic specialises in tailor-made machines, from conveyors to wrapping, from case packers to palletizers and offers complete turnkey end-of-line systems. IMA Phoenix is a leading manufacturer of print&apply and modular labellers for self-adhesive labels, delivering labelling solutions to distributors, system integrators and OEMs.

Focusing on thebakery industry,无论产品——面包、蛋糕、甜甜圈,muffins in pillow bags, doypacks and block bottom bags – the end-of-line equipment preserves the contents and container while providing packaging solutions of all types. These includedisplay packagingsuch as display boxes, wraparound cases, trays with internal or external lids, orsolutions for transport: RSC cases, wraparound cases, palletizers.

A closer look at the machines and technologies on show at IBA.

IBA 2023 will be running from October 22-26 in Münich and IMA will be showcasing a number of solutions on Stand B1.310. Visitors will be able to examine the technologies close up and illustrate any specific requirements with IMA FLX staff. The IMA FLX team is always available to discuss a customer’s goals and adapt each solution technically to achieve or exceed those specific targets. All aspects are considered: from increasing output to reducing operating costs, handling innovative packaging materials or minimising human intervention, even ultrasonic sealing and M.A.P. systems as required.

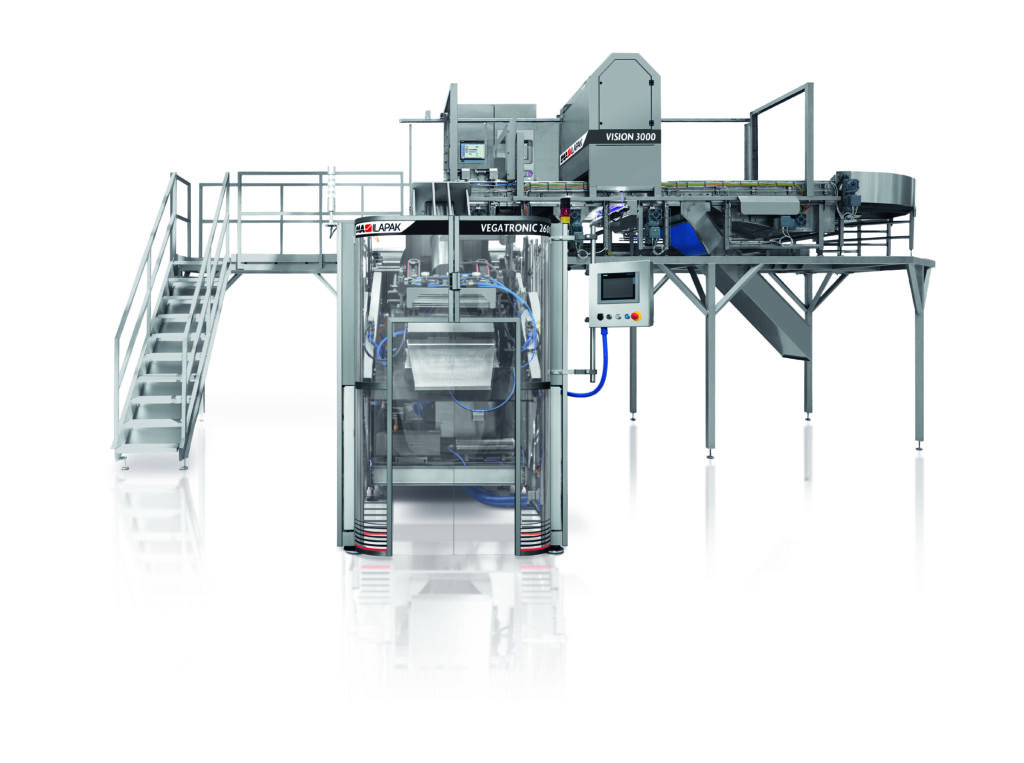

- COMPLETE BAGGING LINE FOR BREAD ROLLS WITH VISION SYSTEM AND VERTICAL FORM-FILL-SEAL EQUIPMENT.

Vision 3000is a vision system using laser technology and will be running in line with an intermittent vertical form-fill-seal machine, theVegatronic 2600.贝克在一起,作为一个完全集成的解决方案eries, these machines will be displayed as a complete bagging line for bread rolls.

By means of a combination of laser and line scan cameras, Vision 3000 guarantees accurate checking and counting operations to verify product height, length, width and surface. Feeding products at high speed, Vision 3000 is so flexible it will handle fresh, par-baked, frozen and raw dough products, whether baguettes, pretzels, rolls, bagels, donuts or croissants.

Based around a 2.5D laser and line scan camera combination, which generates real-time, overlaid images of the product flow, the software calculates when the target number per pack has been reached. Currently the fastest available camera technology on the market, Vision 3000 also provides quality control capabilities, screening for deformed or damaged products, such as bent or broken baguettes. Furthermore, the system can be integrated with a metal detector, sharing a reject system with the quality control module. IMA Ilapak makes sure that whatever needs to go from freezer to box or bag is exactly what the customer wants.

Vision 3000 will be seen feeding theVegatronic 2600with a film buffer, an exclusive feature to avoid downtime. According to product and gentle handling requirements, Vegatronic 2600 can operate with 30, 45 or 60-degree inclination. Bag width is up to 580mm with a maximum film width of 1200 mm. Small or large bags can be used to pack fresh or frozen rolls, croissants, bagels, muffins and more. Flexibility is enhanced thanks to solutions increasing line efficiency and features designed to facilitate changeover procedures and minimise downtime, such as thefilm buffering function allowing the film roll to be changed without stopping the machine.

Completing the benefits of Vegatronic 2600, the open-frame design offers easy access for fast servicing and maintenance, and boasting the highest seal pressure on the market, gas tight seals are fully guaranteed.

- FLOW WRAPPING SOLUTIONS AND LONG-DWELL SEALING USING NEW SUSTAINABLE MATERIALS.

On show at IBA 2023,Delta 3000is one of the market’s best-known flow wrapping machines offeringM.A.P,hermetic sealingandhygienic design.

A key feature available on Delta 3000 will be demonstrated at IBA and regardslong-dwell sealingtechnology toensure hermetic seals for products processed in a modified atmosphere.In view of a growing trend towardssustainable packaging materials, typically hard to handle, containing high proportions ofpaperorrecyclable mono-material, plastic based on PE or PP, at the show, the Delta 3000 will demonstrate its long-dwell sealing capabilities which cover severalnew materialsand enable companies to be well prepared for thefuture.

TheDelta 3000, whencoupled with the VACMAP™system,ensures the same shelf-life standards as thermoforming solutions, but with considerablylower costs.Film is less expensive and minimal operator intervention keepslabour costs to a minimum, even when changeover is performed.

Furthermore, less material is used by a flow wrapping platform than a thermoforming solution, thus placing less wrapping film/material on the market and consequently in the environment.

Higher throughput and exceptional flexibility are hallmarks of the Delta 3000 combined with VACMAP™as it easily handles multiple sizes compared to thermoforming technology. By switching off the vacuum function and reverting to a normal gas flushing system, wrapping speed can be further increased. And to make the fresh bakery products appealing to customers, unlike thermoformed packaging solutions, the entire package can be printed to enhance the perceived quality.

IMA flow wrappers, integrated with the VACMAP™system, represent a valid and cost-effective alternative to thermoforming solutions, combining vacuum and modified atmosphere packaging (M.A.P.) in a single solution.

Moreover, longitudinal sealing of packages using ultrasonic sealing technology is available on most IMA flow wrappers. This system enables you to work with different film structures, maintenance is minimal, and no hardware adjustments are required. Product contamination does not pose a threat to sealing capability, which is fully air-tight, and the limited sealing size saves significant quantities of film and related costs.

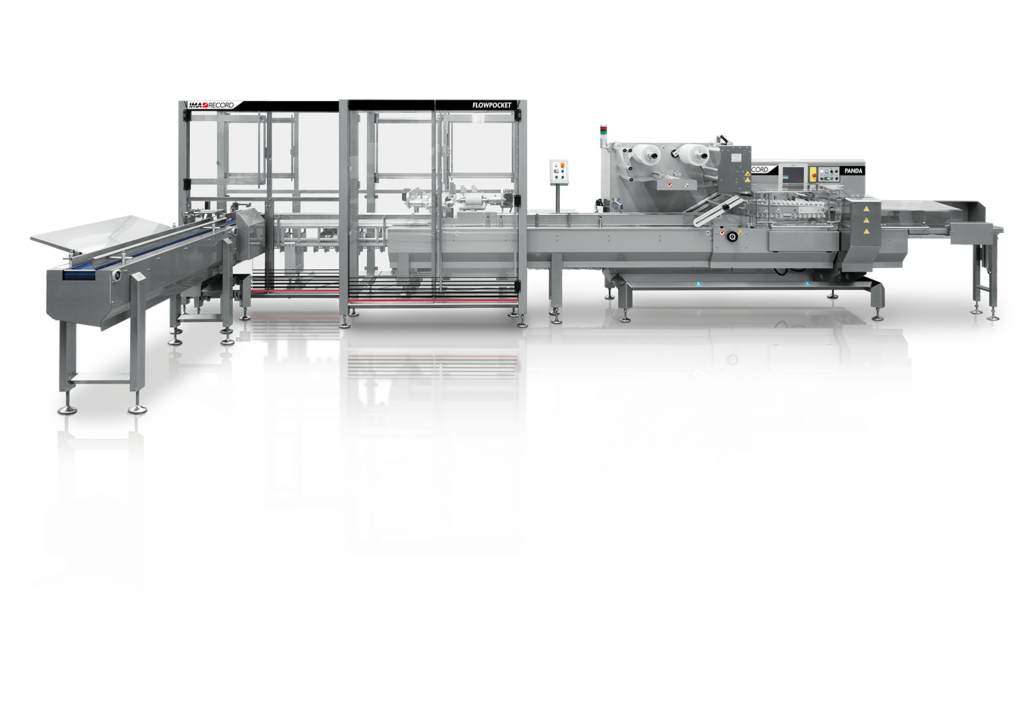

- HORIZONTAL FORM-FILL-SEAL MACHINE COMBINED WITH AN AUTOMATIC LOADING SYSTEM PROCESSING BUNS.

Synchronising the stages of a production line improves efficiency and this is one of the key benefits seen when usingFLOWPOCKETby IMA Record to automatically load buns onto the BS RS (Bottom Seal / Rotating Seal) version of the PANDA flow wrapping machine.

Perfect for a broad range of regular, small and medium-sized products,PANDA BS RSreaches an output of up to 300 ppm. At IBA 2023, the line will be equipped to seal mono-material plastic PE film as well as compostable barrier material. Sealing packets of buns with a rotating jaw, PANDA is fed using the extremely flexible FLOWPOCKET. Featuring 3 pocket trains, FLOWPOCKET channels the buns into independent pockets, so that the process can be synched more precisely along the line. In the exhibited solution, groups of 2 buns are assembled, one pair above the other. A perfect alternative to pick&place systems, FLOWPOCKET is easy to set up, quick to implement changeover and synchronised to perfection.

Insight into future trends and technologies at IBA 2023. Satisfying the need for tangible answers.

Sustainabilityis a common topic across a broad variety of industries, even more so when it comes to the food packaging sector. In an effort to support companies needing to achieve ambitious targets and lay claim to a sustainable approach, IMA has dedicated significant resources to researching innovative packaging solutions.

Originally established in 2016 at the IMA Ilapak facility,IMA OPENLabis now a network of laboratories and testing areas with different locations within the IMA Group:new materials are first investigated in a high-tech laboratory and then tested on fully working packaging lines. Extensive trials are enabling IMA to help industry players and prepare tangible solutions to meet current and future needs in terms of sustainable packaging materials, continually influenced by an evolving legislative scenario.

Focusing on flexibility as a rewarding strategy, IMA has been able to adapt its packaging solutions and give its customers a competitive advantage.Long-dwell sealing solutions是目前最有趣的未来the sector, even if not all of today’s regulations insist on sustainable packaging materials. Such sealing technologies will undoubtedly be essential within a few years, making the investment a sensible option today.

As the need to eliminate preservatives in advanced markets increases, replacing standard technologies with M.A.P. systems, IMA FLX is well placed to offer a variety of alternative packaging solutions, from simple and essential machines to sophisticated, customised lines.

Be sure to visit IMA at IBA 2023. Stand B1.310 in Münich, Germany, from October 22 – 26, 2023.

To prevent the spread and development of altering or pathogenic micro-organisms. The food industry is required to comply with high hygiene standards. One of the most feared events is biofilm formation. Research is focussed on the development of technologies to prevent it or mitigate its consequences.

To prevent the spread and development of altering or pathogenic micro-organisms. The food industry is required to comply with high hygiene standards. One of the most feared events is biofilm formation. Research is focussed on the development of technologies to prevent it or mitigate its consequences.

Use of the electronic nose to detect adulteration in tomato concentrate.

Use of the electronic nose to detect adulteration in tomato concentrate. Numerical modeling on the effect of micro-aeration on the thermal properties of chocolate.

Numerical modeling on the effect of micro-aeration on the thermal properties of chocolate. New technology for the production of yeast-free pizza.

New technology for the production of yeast-free pizza.